Owner, Senior Technician and Ceramicist at Ceramident

It is always daunting for any laboratory to enter the digital arena that is currently making huge waves in dentistry. Ceramident took the step into digital over 12 years ago with our first in-house Zirkonzahn milling unit. Subsequent to this, we bought our second milling unit and have never looked back.

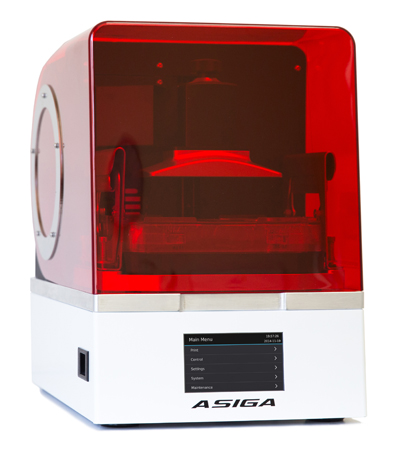

Over the last few years the talk about town has been 3D printing and how this will co-exist within already busy laboratories. Once again laboratories are left with making the decision whether or not to explore this new avenue. Will it aid in producing the high end products expected of us? How will we make it work within our already existing digital workflow? After months of deliberation on which system to invest in, Ceramident decided to take the plunge and purchase the Asiga Max UV 3D printer.

And we have never looked back.

What has this meant for us as a laboratory? We can now offer additional services to our clients, such as clear aligner therapy. We can present services such as implant planning and printing of surgical guide stents for implant placement, digital wax ups for case planning and mock ups for patients to see what the final restorations will look like. We can print temporary restorations as well.

The laboratory operates cleaner, more efficiently and allows us the time to work on other cases while the printer does its job.

We have been ecstatic about our printer, which is why we are happy to announce the arrival of our SECOND Asiga UV MAX Printer.

Cheers to many more happy printing years.